Many SG&A improvement initiatives and cost-reduction measures look like a success on paper when in fact tremendous value was left on the table. For some, it was because the strategy lacked a sufficiently granular evaluation of opportunities and trade-offs. This alone is enough to undermine the benefit of hitting a savings target while sacrificing far more than necessary in the process.

But another opportunity often missed is when the strategy doesn’t take into account the value of the interrelationships between people and processes, and the potential of these interrelationships to generate future value within the new organizational design.

Proudfoot News

The latest in operational and digital transformation through people.

Dennis Santare

Recent Posts

Organizational redesign: Why cut back when you can lean forward?

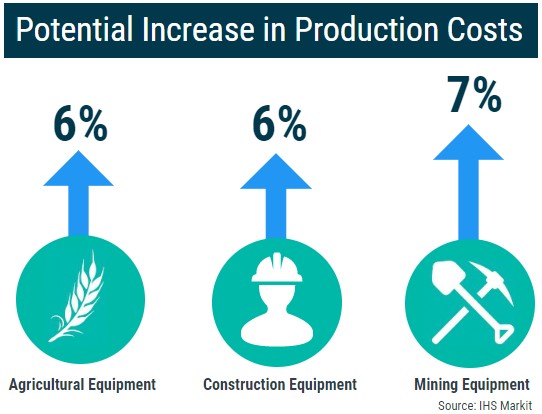

Trade tariffs are especially problematic for heavy equipment manufacturers, as many rely heavily on cross-border supply chains. The tariffs could represent an increase in costs of production by 6% for agriculture and construction equipment and 7% for mining equipment, according to an IHS Markit/AEM report.

Many equipment manufacturers are not able to pass the rising cost of steel to their customers. But the costs have to be offset somehow, leading many manufacturers to look for fresh approaches to eliminate longstanding supply chain inefficiencies and increase productivity.

Beyond low-hanging fruit: How to reach the next level of productivity

Most manufacturers—even successful ones—aren’t seeing anywhere near the levels of productivity that their operations are capable of. It’s not for lack of trying; when embarking on a continuous improvement journey to drive excellence in productivity, manufacturers often experience steady progress in the beginning but eventually run into a wall. After all the quick wins have been exhausted, it can become increasingly difficult to capture substantial productivity gains as the project progresses.

How do you go beyond low-hanging fruit to reach that next level of productivity?

The results from implementing a continuous improvement program can diminish over time for a number of reasons.

What if you could transform your contact center and increase calls-per-hour by 23%?

For many businesses, improving contact center performance and efficiency represents one of the fastest ways to achieve significant cost savings and revenue growth. Crucial to the success of every contact center is creating a healthy balance between outstanding customer service, employee satisfaction, and cost efficiency. Accomplishing all three of these goals in the most efficient way possible can seem like a big challenge, but it’s an even bigger opportunity to maximize your return on investment in this critical function.

So how do you enable your contact center to deliver better results at a lower cost?

Posts by Tag

- change (45)

- behavior (41)

- leadership (36)

- operations (34)

- people (28)

- productivity (24)

- advisors (20)

- mining (20)

- CEO (18)

- news (18)

- people solutions (15)

- challenges (13)

- efficiency (13)

- growth (13)

- management (13)

- execution (12)

- operational transformation (12)

- behaviors (11)

- change management (11)

- human capital (11)

- consulting (10)

- transformation (10)

- operational excellence (9)

- coaching (8)

- industry (8)

- safe operations (8)

- safety (8)

- skills (8)

- technology (8)

- risk (7)

- talent (7)

- customer service (6)

- proudfoot (6)

- revenue growth (6)

- sustainable (6)

- awards (5)

- banking (5)

- consistency (5)

- risk management (5)

- c-suite peer review (4)

- consultancy (4)

- innovation (4)

- lean forward (4)

- manufacturing (4)

- motivation (4)

- sales (4)

- strategy (4)

- supply chain (4)

- top challenges (4)

- working capital (4)

- affordable care act (3)

- costs (3)

- development (3)

- health care (3)

- insurance (3)

- maintenance (3)

- oil & gas (3)

- revenue (3)

- shortage (3)

- turnover (3)

- IT (2)

- MRO (2)

- alignment (2)

- business solutions (2)

- communication (2)

- consumer goods (2)

- digital (2)

- energy (2)

- event (2)

- events (2)

- improvement (2)

- infographic (2)

- internal teams (2)

- morale (2)

- mortality (2)

- video (2)

- O2R (1)

- South Africa (1)

- able (1)

- acquisition (1)

- aerospace (1)

- america (1)

- atlanta (1)

- automotive (1)

- aviation (1)

- benchmarking (1)

- big data (1)

- bronze (1)

- business (1)

- cement (1)

- children (1)

- community (1)

- consumer packaged goods (1)

- contactcenter (1)

- continuous improvement (1)

- controlling (1)

- cost (1)

- crisis (1)

- customer (1)

- digital transformation (1)

- digitization (1)

- downturn (1)

- employee (1)

- employee engagement (1)

- employees (1)

- employment (1)

- enagagement (1)

- engaged (1)

- engagement (1)

- engineering (1)

- fish (1)

- fleet (1)

- food (1)

- giving back (1)

- initiatives (1)

- investment (1)

- larry keeley (1)

- leading (1)

- lean (1)

- london (1)

- merger (1)

- operations consulting (1)

- organizational design (1)

- performance (1)

- petrochemicals (1)

- pharma (1)

- pond (1)

- problem solving (1)

- procurement (1)

- project prioritization (1)

- quality assurance (1)

- readiness (1)

- ready (1)

- refineries (1)

- six sigma (1)

- summit (1)

- supervisors (1)

- tariffs (1)

- throughput (1)

- training (1)

- united way (1)

- willing (1)